Understanding Precision CNC Machining Parts Manufacturing

In today’s competitive industrial landscape, precision CNC machining parts manufacturers play an essential role in ensuring the success of various sectors, from aerospace to automotive, from electronics to medical devices. At DeepMould, we specialize in delivering high-quality, meticulously crafted components that meet the ever-evolving demands of these industries.

What is CNC Machining?

CNC (Computer Numerical Control) machining is a manufacturing process that utilizes computerized controls to operate machines and tools. This technique allows for the precise shaping of materials, including metals, plastics, and composites through a series of cutting and drilling operations. By converting digital designs into physical parts, CNC machining offers unparalleled accuracy, consistency, and efficiency.

Why Choose Precision CNC Machining Parts?

The need for precision in manufacturing cannot be overstated. Here are a few reasons why precision CNC machining parts are essential:

- High Tolerance Levels: CNC machining is capable of achieving incredibly tight tolerances, which is critical for components that must fit together seamlessly.

- Complex Geometries: The technology allows the production of intricate designs that would be difficult or impossible to achieve with traditional manufacturing methods.

- Consistency: With CNC machining, every part produced is nearly identical, ensuring uniform quality and performance across all components.

- Speed: Automated processes reduce production time, allowing manufacturers to respond quickly to market demands.

- Material Versatility: CNC machining can work with a variety of materials, making it suitable for many applications.

The Process of CNC Machining

A successful CNC machining operation involves several essential steps:

- Design Creation: An engineer creates a detailed digital blueprint using CAD (Computer-Aided Design) software.

- Conversion to G-code: The CAD file is converted into G-code, a programming language that CNC machines understand.

- Material Selection: The right material is selected based on the end use of the component.

- Machining: The CNC machine cuts, drills, and shapes the material according to the G-code instructions.

- Quality Control: Finally, each component undergoes rigorous inspection to ensure it meets specified tolerances and quality standards.

DeepMould's Expertise in Metal Fabrication

At DeepMould, our expertise in precision CNC machining parts manufacturing allows us to stand out in the metal fabrication industry. Our state-of-the-art facilities are equipped with the latest CNC technology, enabling us to provide highly accurate and reliable parts for a variety of applications.

Quality Assurance

Quality is not just a priority at DeepMould; it is embedded in our culture. We implement stringent quality control measures throughout the manufacturing process, ensuring that every component not only meets but exceeds industry standards. Our quality assurance practices include:

- Regular calibration of CNC machines

- Use of advanced inspection technologies, such as CMM (Coordinate Measuring Machine)

- Thorough documentation of quality processes

- Continuous training for our staff on the latest quality standards

Custom Solutions

Understanding that each client may have unique requirements, we offer tailored solutions in our manufacturing processes. Our team collaborates closely with clients to understand their specific needs, providing:

- Custom designs based on client specifications

- Rapid prototyping services

- Small to large production runs

- Adaptation of designs for manufacturability

Industries Benefiting from CNC Machining

The versatility of precision CNC machining parts means they find application across a wide array of sectors. Some of the key industries we serve at DeepMould include:

- Aerospace: High-performance components are critical in aerospace applications, where safety and reliability are paramount.

- Automotive: We provide precision parts that contribute to the longevity and performance of vehicles.

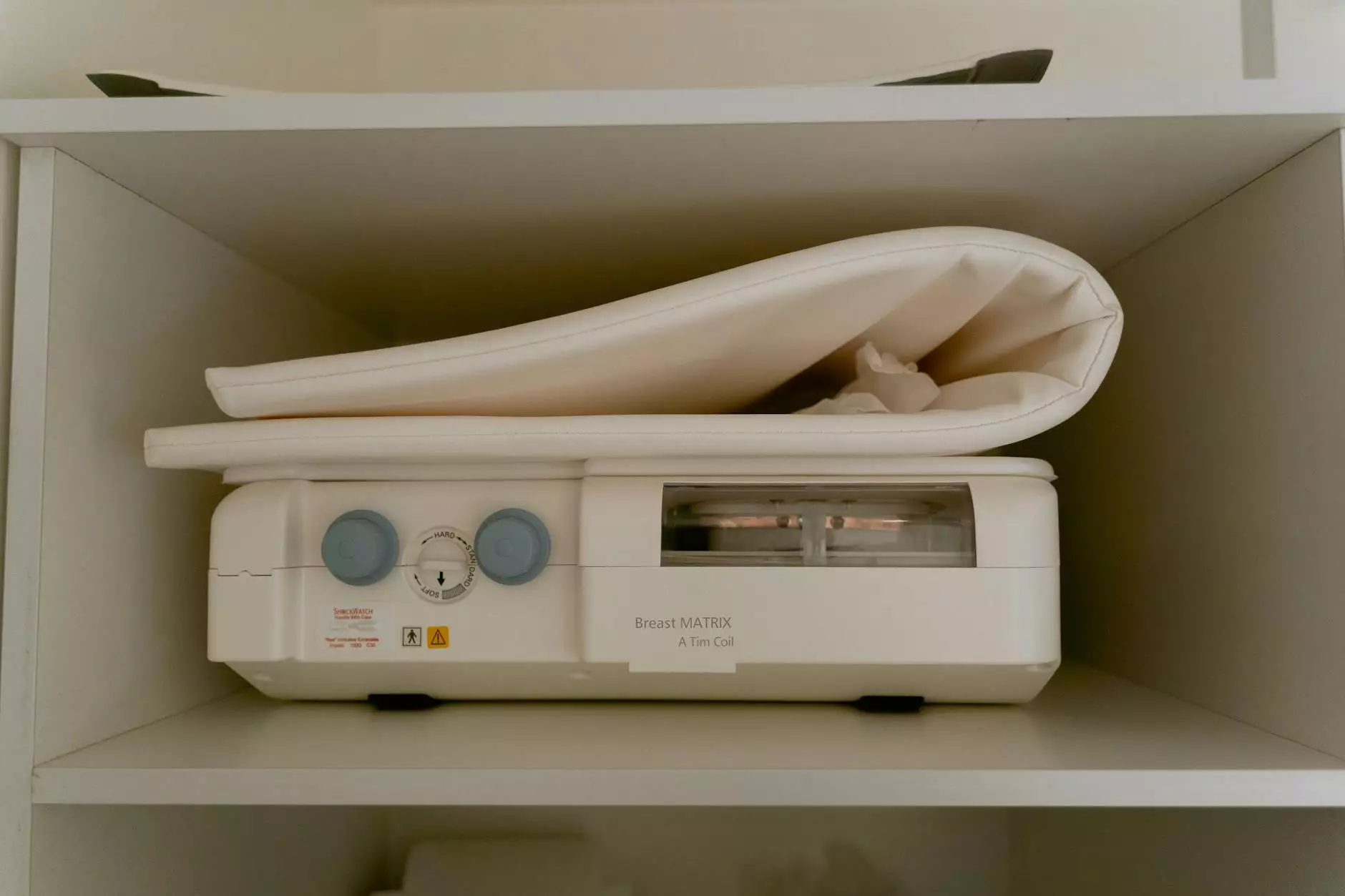

- Medical Devices: The medical sector requires components that are not only precise but also compliant with strict regulatory standards.

- Electronics: CNC machining supplies intricate parts that are fundamental to function and efficiency in electronic devices.

- Industrial Machinery: Our machined components ensure the optimal operation of vital machinery in various industries.

Future Trends in CNC Machining

The future of precision CNC machining parts manufacturing looks promising as technology continues to evolve. Here are some trends to watch:

- Increased Automation: Automation will further enhance productivity, reduce costs, and improve efficiency.

- Advanced Materials: The development of new materials, including composites and smart materials, will open up new possibilities for precision machining.

- Integration of IoT: The Internet of Things will enable real-time monitoring of machines, enhancing maintenance and reducing downtime.

- Sustainability Practices: There will be a stronger focus on sustainable manufacturing practices, including waste reduction and environmental impact considerations.

Why Trust DeepMould?

Choosing the right precision CNC machining parts manufacturer is crucial for the success of your projects. Here’s why you can trust DeepMould:

- Experience: With years of industry experience, we have honed our skills and capabilities.

- Expert Team: Our engineers and machinists are highly skilled and continually trained on the latest technologies and trends.

- Client-Focused Approach: We prioritize our clients, working hand-in-hand to achieve their specific goals and objectives.

- Competitive Pricing: By optimizing our processes, we provide high-quality products at competitive prices.

- Technical Support: Our team offers unparalleled support throughout the manufacturing process and beyond.

Conclusion

In conclusion, as the demand for precision engineering continues to rise, the role of precision CNC machining parts manufacturers becomes ever more significant. At DeepMould, we leverage our expertise to deliver outstanding metal fabrication solutions that meet the highest standards of quality and precision. If you are looking for a reliable partner in your manufacturing journey, we invite you to reach out to us today and discover how we can help you succeed.